Here are some key steps and techniques for quality control in casting: The study of casting helps us predict the casting quality and defects without doing actual castings, and hence, save time, money and resources. Conduct a thorough analysis of the casting design to minimize potential defects, such as shrinkage, porosity, or uneven cooling.

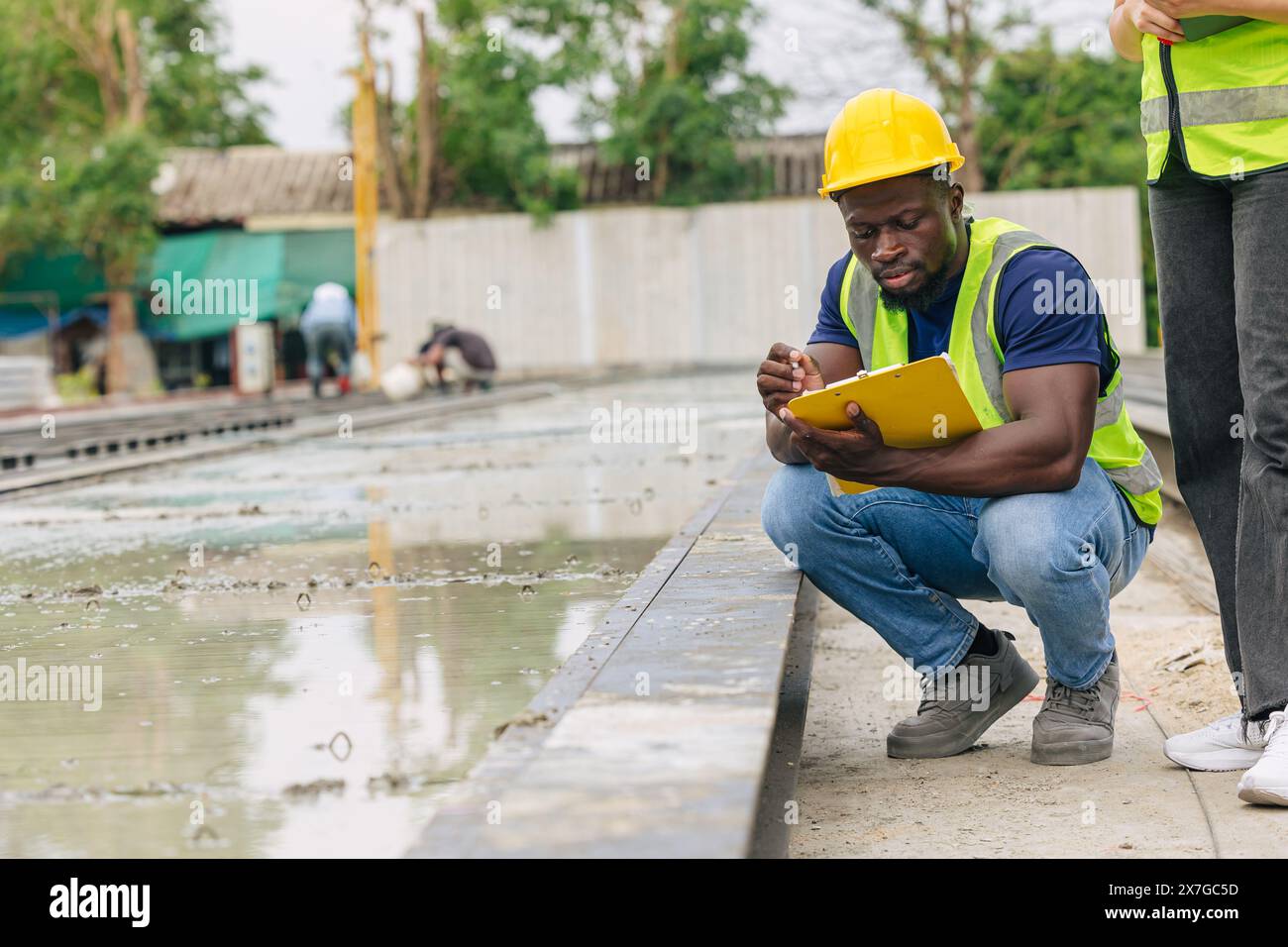

Engineer quality control in Precast concrete casting manufacturing

Castings can be difficult to get right.

These measures could include changes in process control, worker training, or modifications in the testing and inspection procedures.

Quality control is a continuous process. Regular monitoring of the casting process and periodic audits of the quality control system are essential to ensure its effectiveness. Along with the industry 4.0, smart factory is receiving great attention worldwide. In particular, quality control is the most important element of the production system.

Of the many processes in manufacturing, the early process, casting is the biggest role in modern root industry. Casting is a manufacturing process in which a liquid material is usually poured into a mold to harden for solidify This system of metamodels reported in [2] has been proved to be of considerable support to manage the two important issues of quality and productivity in continuous casting process. How this system has been developed further to help managing quality is the major concern of the present paper.

Quality control and inspection methods are critical to the success of precision casting processes.

This enables the casting industry to control the process variabilities and their associated quality issues and make cast products right first time which is an important aspect of quality control (antony et al., 2021). As such, sand casting is one of the most popular and efficient casting methods for small and medium parts since it gives good properties of parts. Quality improvement of the sand casting process it is also important to note that the quality of the casting depends on the pattern and the quality of the sand [20]. These measures could include changes in process control, worker training, or modifications in the testing and inspection procedures.

Quality control is a continuous process. Regular monitoring of the casting process and periodic audits of the quality control system are essential to ensure its effectiveness. The monitoring of casting quality is very important to ensure the safe operation of casting processes. The proposed method reduces the dimensionality of the original data by the projection of the data onto a

Quality control of casting materials on example of cast iron, wnt, warszawa 1999, page 40.